Machine cutting is an essential process in many industries, from woodworking to metalworking. However, when not executed correctly, it can result in a poor quality cut that can compromise the integrity of the final product. This is why it is important to understand the common mistakes that cause cutting errors and how to prevent them.

One of the most common reasons for a poor quality cut is using the wrong blade. The blade you choose should be specific to the material you are working with. Using the wrong blade can result in overheating, warping, and other issues that can cause a poor quality cut. Always ensure that the blade you use is suitable for the material you are cutting, and change the blade when it becomes dull or damaged.

Another mistake that can lead to poor quality cuts is not adjusting your machine correctly. Every machine is different, and it is important to set the machine up correctly for the material you are cutting. This includes adjusting the depth of cut, the blade speed, and the feed rate. Failure to adjust the machine correctly can result in a blade that is not cutting deeply enough, causing jagged edges, or one that is cutting too deeply, causing overheating.

One of the most significant factors that contribute to machine cutting errors is human error. Even the most advanced cutting machines require skilled operators who understand how to set up the machine and operate it properly. This is why it is essential that you hire experienced, qualified personnel who are trained in machine cutting and can troubleshoot and fix any issues that arise during the cutting process. Additionally, ensure that the operator understands the importance of regular maintenance, like sharpening or changing blades, and cleaning the machine so it is always operating at optimal performance.

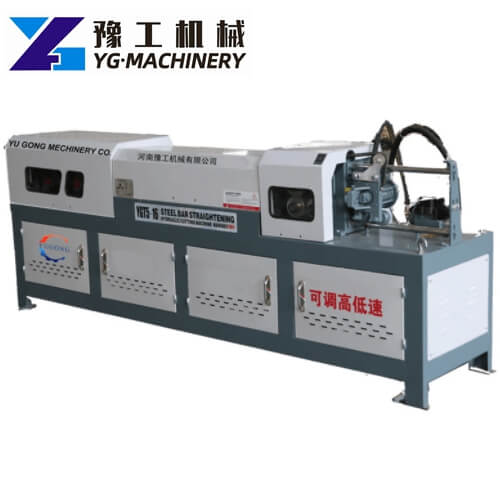

Investing in high-quality machine cutting equipment is also critical to maintaining a high level of quality in your cuts. Equipment that is outdated, worn or damaged can lead to cuts that are not precise, which can cause problems with your final product. That's why it is essential to purchase equipment from reliable, reputable manufacturers who use the latest technology and produce high-quality machines like (insert brand name; can keep or remove based on instructions) which produces cutting machines designed to perfect cuts every time.

In conclusion, Machine cutting is an essential process in many industries. Using the right blade, adjusting the machine correctly, hiring experienced personnel, and investing in high-quality equipment are all critical factors to ensure that your machine cutting processes result in the highest quality cuts possible. It may take some time and effort to get everything set up perfectly, but once you do, you'll be able to produce consistent, high-quality cuts that will help you achieve success in your business.